1. Electric type: driven by high-performance carbon brush motor, voltage 220V, frequency 50-60Hz, power 0.8~2.2KW.

2. Pneumatic type: driven by a pneumatic motor, with an air working pressure of 1.0~3.0MPa and a gas consumption of 1000-1500L/min.

3. Suitable for workplaces with flammable and explosive hazards.

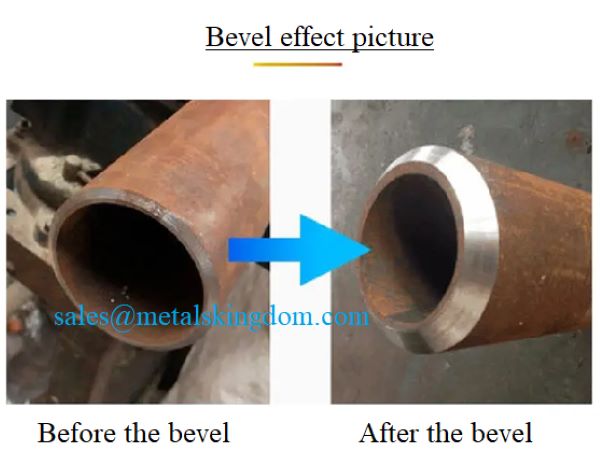

1.Product Introduction

The internal expansion type pipeline beveling machine is an electric tool used for processing steel pipe end faces. It adopts a single-phase AC 220V power supply with double insulation treatment. The internal clamping device is fixed, manually fed, and has a handheld pipe internal installation structure. It uses an internal clamping 3 claw self centering function to quickly install inside the pipeline, and a high-performance driving method to drive the cutter head to rotate for internal and external beveling and cutting of the pipe end. The internal expansion type beveling machine has the advantages of small size, light weight, high power, high-quality beveling, high efficiency, wide applicability, low labor intensity for workers, and high safety. It is widely used for beveling cutting before pipeline welding in industries such as petroleum, chemical, natural gas, shipbuilding, nuclear industry, food, boiler, pharmaceutical, and field pipe construction.

2. Product features

2.1 Inner diameter installation type beveling machine.

2.2 Capable of chamfering various materials, including carbon steel, stainless steel, and alloy steel.

2.3 Quick installation, completed in a few minutes.

2.4 The cutting process is entirely cold cutting and does not affect the pipeline.

2.5 It is particularly suitable for working in narrow spaces.

2.6 The tensioning structure automatically aligns and is easy to install.

2.7 Low cost and affordable price.

3. Driver parameters

3.1 Electric type: driven by high-performance carbon brush motor, voltage 220V, frequency 50-60Hz, power 0.8~2.2KW.

3.2 Pneumatic type: driven by a pneumatic motor, with an air working pressure of 1.0~3.0MPa and a gas consumption of 1000-1500L/min; Suitable for workplaces with flammable and explosive hazards.

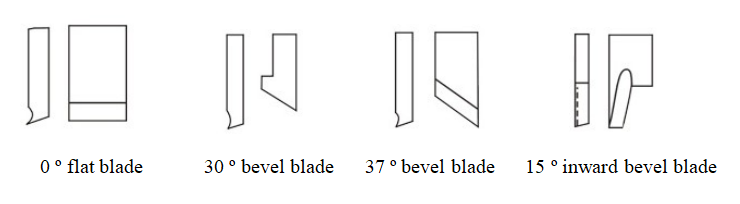

4. Configure cutting tools

Note: For other angles, please contact our company.

5. Selection parameters

Electric model | Pneumatic model | Processing range (mm) | Wall thickness (mm) | Cutter head speed R/min |

ISE-30 | ISP-30 | Φ16-28 | ≤ 15 | 60 |

ISE-80 | ISP-80 | Φ28-76 | ≤15 | 50 |

ISE-150 | ISP-150 | Φ65-159 | ≤15 | 35 |

ISE-250 | ISP-250 | Φ80-240 | ≤15 | 16 |

ISE-250-2 | ISP-250-2 | Φ80-240 | ≤75 | 16 |

ISE-350 | ISP-350 | Φ150-330 | ≤15 | 14 |

ISE-350-2 | ISP-350-2 | Φ150-330 | ≤75 | 14 |

ISE-426 | ISE-426 | Φ250-426 | ≤15 | 10 |

ISE-426-2 | ISP-426-2 | Φ250-426 | ≤75 | 10 |

ISE-610 | ISP-610 | Φ300-600 | ≤15 | 8 |

ISE-610-2 | ISP-610-2 | Φ300-600 | ≤75 | 8 |

6. Product composition

6.1 Electric motor: It is a single-phase electric motor and is made into a self ventilated protective type. The casing and handle cover are made of thermoplastic engineering plastic, and thermosetting engineering plastic is pressed between the armature shaft and the iron core to form a double insulation structure.

6.2 Body: The box is equipped with a one stage gear reduction mechanism.

6.3 Feed device: Connected by fine thread, nut and core shaft thread, rotate the nut to complete axial feed.

6.4 Clamping device: internal expansion clamping.

6.5 cutterhead: The overall cutterhead is connected to the spindle.

6.6 Tools: Various types of tools.

7. Usage method

7.1 Select the corresponding tensioning block according to the inner diameter of the pipe, install it in the groove of the support shaft and the stopper plate, and connect it with the tension rod and the support shaft with a spring.

7.2 Insert the installed support shaft assembly into the beveled pipe, use a hand to rotate the square head of the pull rod, and firmly fix the support shaft assembly back onto the beveled pipe.

7.3 Install the machine body on the support shaft and rotate the feed handle to screw the internal thread of the machine body into the thread of the support shaft.

7.4 Install the blade and clamp it in the groove of the cutter head with screws according to the diameter of the pipe. Note: Use an alloy blade to cut the gas cut section, and then use a high-speed steel blade for cutting.

7.5 Install the motor, insert the tapered gear shaft into the tapered hole of the motor, and then insert it into the motor interface hole of the beveling machine, and tighten it with screws.

7.6 Connect the power supply to 220V and perform a jog test run. After the machine runs smoothly, start rotating the feed handle for bevel processing. Be careful not to feed too quickly when there are gas cutting marks to prevent cutting or damage to the machine. This machine is equipped with three types of cutting tools: 0 º, 30 º, and 37 º, and the user can customize the bevel form.

7.7 After the bevel processing is completed, cut off the power, clean the dirt on the machine body, add oil and put it into the packaging box.