ISC-25 C-Type External Clamp Beveling Machine

1.The c-type external clamp beveling machine is a portable beveling machine designed by our company for narrow space and small diameter pipelines. It adopts an external clamp clamping device, with one fixture for each outer diameter pipe, precise positioning, and easy disassembly and assembly;

2.Simultaneously adopting an automatic advance and retreat blade design, greatly reducing labor intensity, improving work efficiency, and ensuring the service life of the machine;

3.This product is suitable for pipe groove processing and on-site maintenance of professional equipment such as water-cooled wall superheaters, reheaters, gas, boilers, and thermal power plants. It meets the processing requirements of narrow working spaces and large maintenance batches in pipeline maintenance sites;

4.Selected high-quality blades with bevel angles of 30 °, 37 °, etc. Can process various grades of carbon steel, alloy steel, stainless steel, and other materials of metal pipes;

5.Adopting external clamp positioning installation, simple and lightweight, precise centering, stable clamping, and easy to use;

6.Configure a specialized motor customized by German company Metabo, with a voltage of 220V, frequency of 50Hz, and power of 1.3KW. Powerful and durability.

1.Product Introduction

The ISC series external clamp electric pipe beveling machine is a lightweight steel pipe beveling machine developed by our company. This series of beveling machines is designed specifically for chamfering steel pipes with narrow inner diameters. This series of steel pipe beveling machines is powered by an AC 220V motor, with an external clamp structure that can automatically feed and is easy to operate; Safe and reliable use. The new design concept and shape, as well as excellent performance, make it at the forefront of groove processing technology. This machine can perform groove and flat flange processing on steel pipes. Regardless of the thickness of the pipe wall, its processing performance and efficiency have irreplaceable advantages compared to traditional processes.

2. Product features

2.1 The c-type external clamp beveling machine is a portable beveling machine designed by our company for narrow space and small diameter pipelines. It adopts an external clamp clamping device, with one fixture for each outer diameter pipe, precise positioning, and easy disassembly and assembly;

2.2 Simultaneously adopting an automatic advance and retreat blade design, greatly reducing labor intensity, improving work efficiency, and ensuring the service life of the machine;

2.3 This product is suitable for pipe groove processing and on-site maintenance of professional equipment such as water-cooled wall superheaters, reheaters, gas, boilers, and thermal power plants. It meets the processing requirements of narrow working spaces and large maintenance batches in pipeline maintenance sites;

2.4 Selected high-quality blades with bevel angles of 30 °, 37 °, etc. Can process various grades of carbon steel, alloy steel, stainless steel, and other materials of metal pipes;

2.5 Adopting external clamp positioning installation, simple and lightweight, precise centering, stable clamping, and easy to use;

2.6 Configure a specialized motor customized by German company Metabo, with a voltage of 220V, frequency of 50Hz, and power of 1.3KW. Powerful and durability.

3. Technical parameters

Model | Processing scope(mm) | Pipe wall thickness(mm) | Net weight/ Weight(Kg) | Cutter specifications | Longitudinal cutting depth(mm) |

ISC-25 | Φ14-25 | 0-8 | 10/15 | L10*10 | 0-22 |

ISC-38 | Φ25-38 | 0-8 | 10/15 | L10*10 | 0-22 |

ISC-45 | Φ25-45 | 0-10 | 10/15 | L12*12 | 0-22 |

ISC-63 | Φ32-63 | 0-10 | 13/18 | L12*12 | 0-22 |

ISC-76 | Φ38-76 | 0-12 | 13/20 | L12*12 | 0-22 |

ISC-83 | Φ51-83 | 0-12 | 16/26 | L12*12 | 0-22 |

ISC-114 | Φ83-114 | 0-12 | 18/30 | L12*12 | 0-22 |

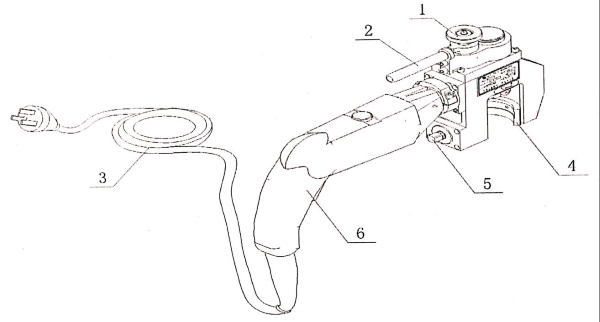

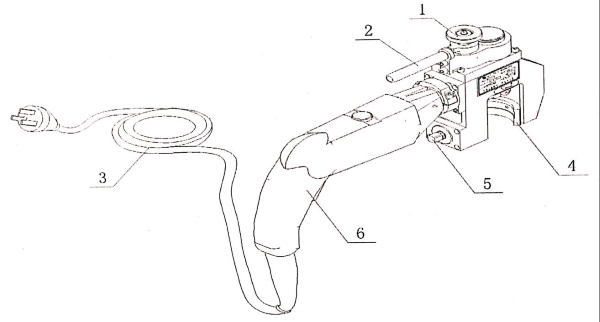

4. Schematic diagram of product structure

1. Feed hand wheel device: When working, rotating the feed hand wheel will achieve feed in or feed out.

2. Handle: When handling equipment, grip the handle tightly.

3. Power cord: Connect the device power supply and do not drag this power cord at any time.

4. Tensioning block: Select the appropriate tensioning block according to the outer diameter of the steel pipe, and fix the equipment on the outer wall of the steel pipe to be processed through a pull rod.

5. Lock nut: Rotate the lock nut to achieve the expansion and contraction of the tension block, securing the equipment to the steel pipe.

6. Motor: The motor has a power of 1300W and is driven by a curved bevel gear. It is clamped with a positioning block and the speed can be adjusted.