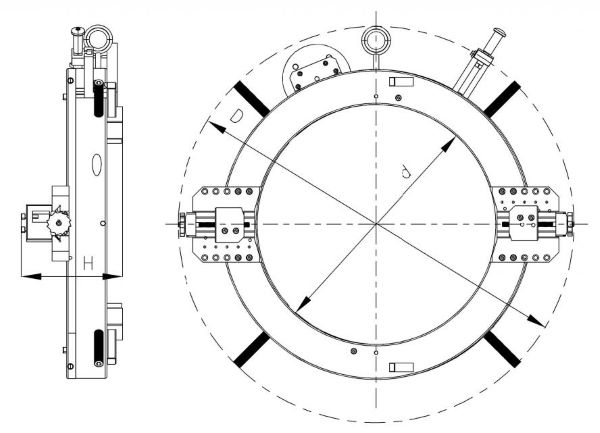

Servo YPE External Stuck Type Pipeline Cutting and Beveling Machine

1.Suitable for processing various heat-resistant steel and stainless steel large-diameter pipes;

2.Online installation, complete the pipe cutting beveling in one go;

3.Small radial net space. Lightweight, suitable for places with complex environments and small spaces;

4.Completely cold cut without affecting the material of the pipeline, ensuring its wide applicability;

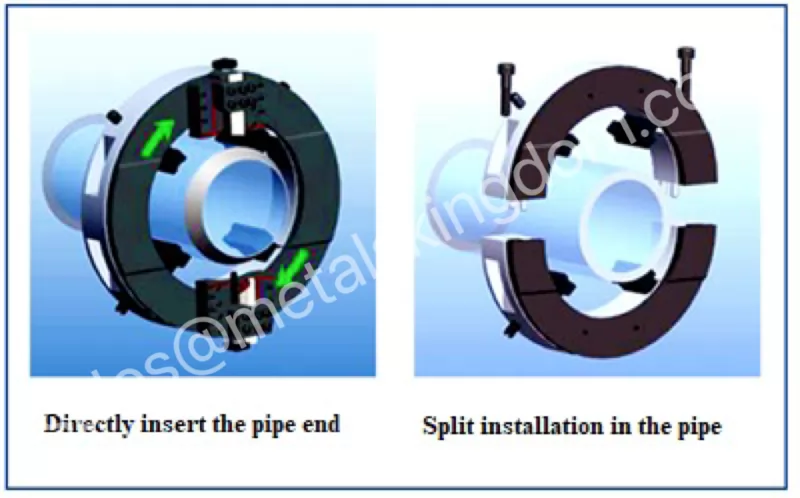

5.Can be split in half, this structure is suitable for situations where there are objects at both ends of the pipe, which are not easy to disassemble or cannot be disassembled;

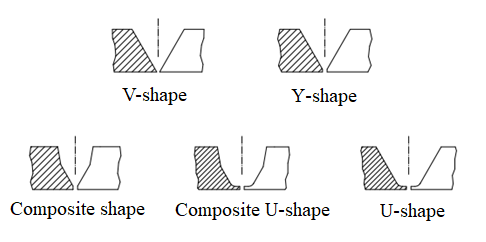

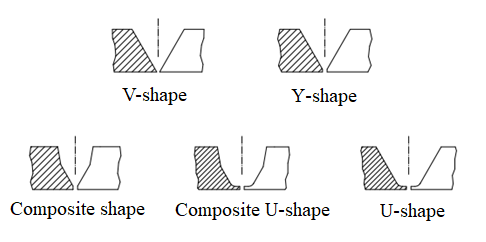

6.Machinable cutting beveling forms: U-shaped, V-shaped, Y-shaped, as well as composite and composite U-shaped;

7.This machine can process U-shaped and V-shaped welds on pipes made of carbon steel, stainless steel, alloy steel and other materials, but also process raised flanges after welding;

1. Product Introduction:

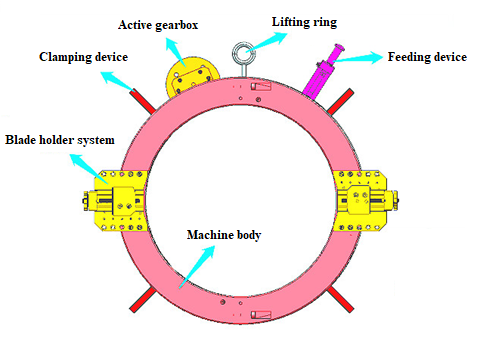

The external stuck type pipeline cutting and beveling machine sets the processing range according to international pipeline standards, and can perform single cutting or single beveling processing on various specifications of pipelines, containers, and flanges. It can also complete cutting and beveling processing simultaneously, and can also perform composite beveling and flange surface processing. Its design is clever, installation and operation are very simple, and the body is a split ring structure, which is very convenient for disassembly and combination. It can be installed at any position of the pipeline. It is a movable pipeline cutting and beveling machine with small radial space, suitable for complex environments and small spaces. Good bevel quality, fast speed, and adjustable cutting amount. Widely applicable for pipeline installation and repair operations in industries such as petroleum, chemical, natural gas, food, boilers, pharmaceuticals, nuclear power, and field management construction.

2. Product features:

1.Suitable for processing various heat-resistant steel and stainless steel large-diameter pipes;

2.Online installation, complete the pipe cutting beveling in one go;

3.Small radial net space. Lightweight, suitable for places with complex environments and small spaces;

4.Completely cold cut without affecting the material of the pipeline, ensuring its wide applicability;

5.Can be split in half, this structure is suitable for situations where there are objects at both ends of the pipe, which are not easy to disassemble or cannot be disassembled;

6.Machinable cutting beveling forms: U-shaped, V-shaped, Y-shaped, as well as composite and composite U-shaped;

7.This machine can process U-shaped and V-shaped welds on pipes made of carbon steel, stainless steel, alloy steel and other materials, but also process raised flanges after welding;

3. Technical parameters:

Model | Specifications | Processing range | Cutting beveling wall thickness | Cutter head speed |

Normal | Overload |

Servo YPE

| 89 | 3” | Φ20-89 | 3/4”-3.5” | ≤20 | - | 34r/min |

168 | 6” | Φ50-168 | 2”-6” | ≤30 | ≤50 | 22r/min |

219 | 8” | Φ69-219 | 2.7”-8” | ≤30 | ≤50 | 15r/min |

273 | 10” | Φ123-273 | 4”-10” | ≤30 | ≤75 | 14r/min |

325 | 12” | Φ157-325 | 6”-12” | ≤30 | ≤75 | 13r/min |

377 | 14” | Φ227-377 | 9”-14” | ≤30 | ≤110 | 12r/min |

426 | 16” | Φ273-426 | 10”-16” | ≤30 | ≤110 | 12r/min |

457 | 18” | Φ307-457 | 12”-18” | ≤30 | ≤110 | 12r/min |

508 | 20” | Φ358-508 | 14”-20” | ≤30 | ≤110 | 12r/min |

560 | 22” | Φ410-560 | 16”-22” | ≤30 | ≤110 | 12r/min |

610 | 24” | Φ460-610 | 18”-24” | ≤30 | ≤110 | 11r/min |

660 | 26” | Φ510-660 | 20”-26” | ≤30 | ≤110 | 11r/min |

711 | 28” | Φ560-711 | 22”-28” | ≤30 | ≤110 | 11r/min |

762 | 30” | Φ610-762 | 24”-30” | ≤30 | ≤110 | 11r/min |

813 | 32” | Φ660-813 | 26”-32” | ≤30 | ≤110 | 10r/min |

863 | 34” | Φ710-863 | 28”-34” | ≤30 | ≤110 | 10r/min |

914 | 36” | Φ762-914 | 30”-36” | ≤30 | ≤110 | 10r/min |

1066 | 42” | Φ914-1066 | 36”-42” | ≤30 | ≤110 | 8r/min |

1230 | 48” | Φ1066-1230 | 42”-48” | ≤30 | ≤110 | 8r/min |

Note: The relevant technical parameters are for reference only. Non-standard products can be designed according to customer requirements. For large diameter pipelines, it is recommended to contact our company for consultation.

4. Driving method:

Driving method | Characteristic | Requirements |

Servo

|

Powerful, low noise, stable performance, high load-bearing capacity, capable of continuous operation

|

Power requirement: 220V 1PH 50/60Hz Power: 2KW, 3KW

|

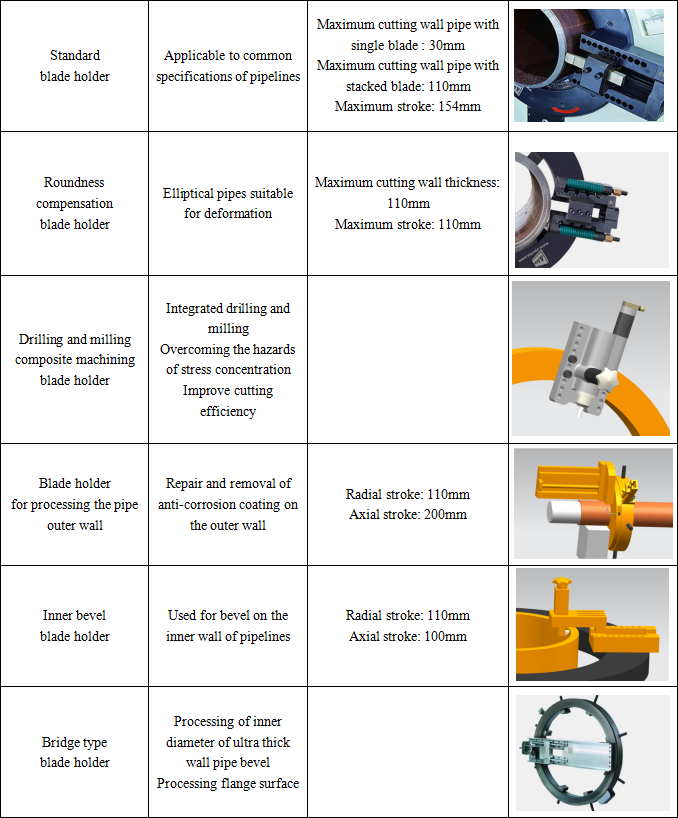

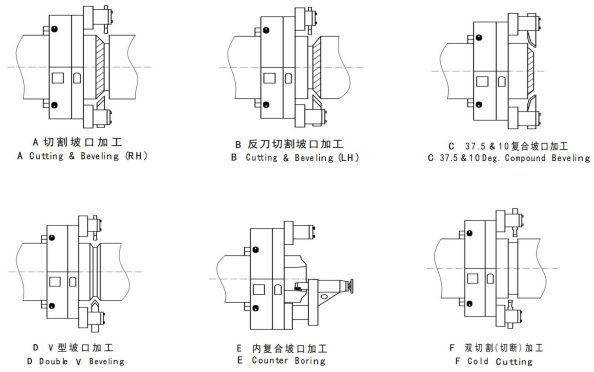

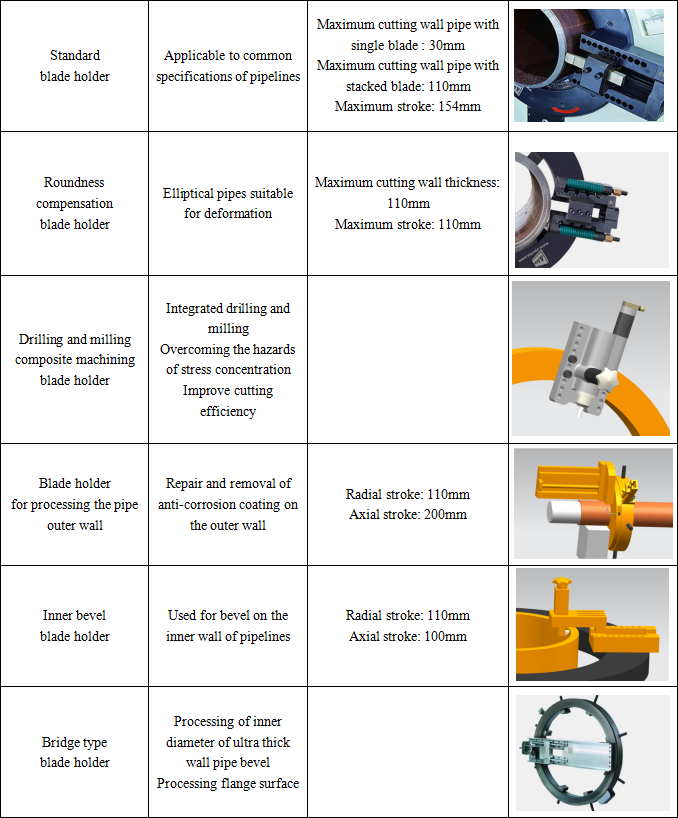

5. Blade holder

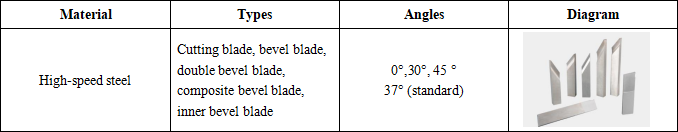

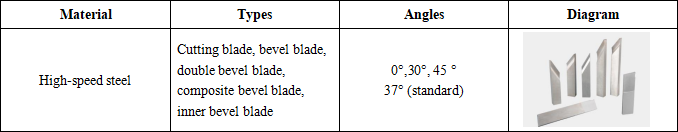

6. Cutting and beveling blades

7. Bevel forms

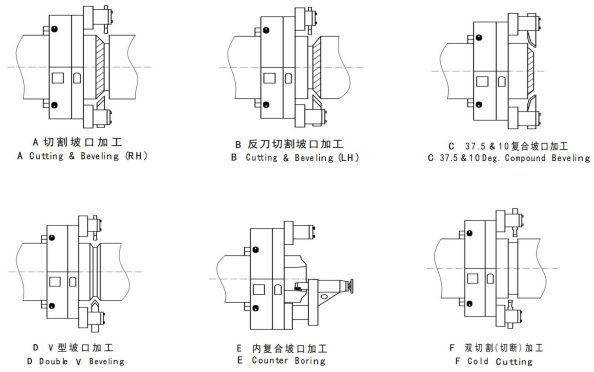

8. Processing diagram

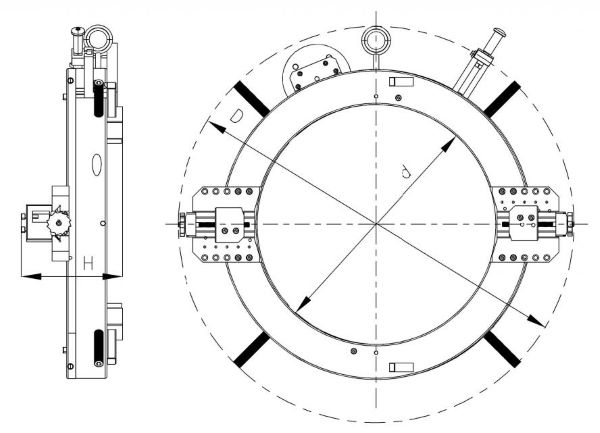

9. Axial and radial clearance charts:

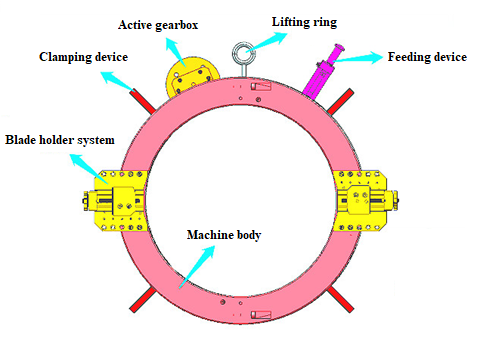

10.Structural schematic diagram