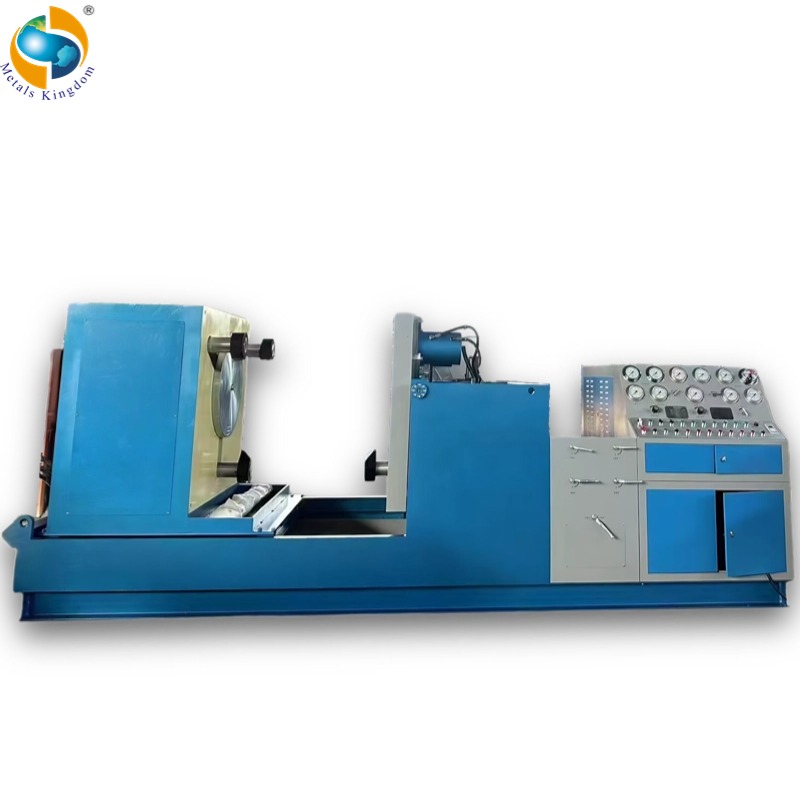

Usually, it is not necessary to conduct strength tests when industrial valves are in use, but if the valve body and valve cover are corroded and damaged, we should conduct strength tests on the valve body and valve cover. For safety valves, inspections such as pressure stabilization and oil return pressure should comply with standards and relevant regulations. Before the valve is replaced, the valve strength test and valve sealing test should be carried out on the hydraulic test bench. 20% of low-pressure valves shall be randomly inspected. If they are unqualified, 100% shall be randomly inspected; all medium-pressure and high-pressure valves shall be tested. Commonly used media for valve pressure testing include water, oil, air, steam, nitrogen, etc. The pressure testing techniques for different industrial valves, including pneumatic valves, are as follows:

1. Pressure test method of gate valve.

The strength test for a gate valve follows the same procedure as that of a globe valve. When it comes to conducting the sealing test for a gate valve, there are two methods that can be employed.

The first method involves increasing the pressure inside the valve to the specified level. This is done by initially opening the gate, then closing it, and swiftly removing the gate valve. The objective here is to inspect the seals on both sides of the gate for any signs of leakage. Alternatively, you can inject the test medium directly into the plug on the valve cover to reach the desired pressure. This approach is known as the intermediate pressure test. It is important to note that this method is not suitable for sealing tests on gate valves with a nominal diameter below DN32 mm.

The second method for raising the test pressure of the valve involves opening the gate, closing it, and then opening the blind plate at one end to check for any leakage on the sealing surface. This process may need to be repeated, adjusting the pressure as necessary, until the valve is deemed qualified. Before conducting the gate sealing test, it is essential to perform a pneumatic test for the gate valve's packing and gasket sealing.

2. Pressure test method of globe control valve and throttle valve

When conducting the strength test for globe control valves and throttle valves, the typical procedure involves placing the fully assembled valve in a pressure test frame. The valve disc is then opened, and the designated medium is injected to reach the specified pressure level. This is done to inspect whether there is any sweating or leakage occurring on the valve body and valve cover. The strength test can also be carried out on individual valve components.

However, it's important to note that the tightness test is exclusive to globe control valves. During this test, the valve stem of the stop valve is positioned vertically, with the valve disc open, and the medium is introduced from the lower end of the valve disc up to the specified pressure level. This allows for an assessment of the packing and gasket. After successfully passing the test, the valve disc is closed, and the other end is opened to check for any potential leaks.

If both the strength and sealing tests are to be performed on the valve, the recommended sequence is to conduct the strength test first. Subsequently, the pressure is reduced to the specified value for the sealing test, and the packing and gasket are examined. Finally, the valve disc is closed, and the outlet port is opened to assess whether there is any leakage occurring on the sealing surface.

3. Pressure test method of ball valve

When conducting the strength test for pneumatic ball valves, it is essential to perform the test with the ball positioned at a semi-open state.

For floating ball valve sealing test: Place the valve in a semi-open state, insert the test medium into one end, and close the other end. Rotate the ball multiple times and open the closed end while closing the valve. During this process, inspect the sealing effectiveness of the packing and gasket. There should be no leaks. Then, inject the test medium from the other end and repeat the same test.

For fixed ball valve sealing test: Rotate the ball several times until it's in a no-load state, then close the fixed ball valve. Introduce the test medium from one end to the specified pressure level and employ a pressure gauge with an accuracy of 0.5 - 1 and a measurement range of 1.6 times the test pressure to evaluate the sealing efficiency at the inlet end. If there is no decompression within the specified time frame, the valve is considered qualified. Subsequently, inject the test medium from the other end and repeat the test.

To further assess the sealing integrity, place the valve in a half-open state, close both ends, and fill the inner cavity with the medium. This allows for an examination of the packing and gaskets under the test pressure, and there should be no leakage.

In the case of three-way ball valves, it is imperative to check the tightness of each position to ensure their proper functioning and sealing effectiveness.

4. Pressure test method of plug valve.

During the strength test of a plug valve, the procedure involves introducing the test medium from one end while keeping the other passages closed. The plug is then rotated to its fully open working position for the test. If there are no signs of leakage, the valve body is considered to be qualified.

For the sealing test, a straight-through cock must maintain the pressure in the cavity at a level similar to that of the passage. The plug is then turned to the closed position, and an inspection is carried out from the other end. Subsequently, the plug is rotated 180 degrees to repeat the aforementioned test.

In the case of a three-way or four-way plug valve, it's essential to maintain pressure in the cavity and one end of the passage simultaneously. The plugs are turned to the closed position, and both the pressure from the right-angle end and the other end are examined simultaneously.

To ensure the integrity of the sealing surfaces, stop the test bench, it is advisable to apply a non-acid dilute lubricant and then conduct the test. During this test, the sealing surfaces should remain leak-free within a predetermined time, and a slight expansion of water droplets is permissible.

The test duration for the plug valve may vary but is typically in the range of 1 to 3 minutes, depending on the nominal diameter.

For gas plug valves, airtightness should be checked at 1.25 times the operating pressure to ensure their proper functioning and sealing.

5. Pressure test method of the diaphragm valve.

During the strength test of a diaphragm valve, the procedure involves introducing the medium from either end while keeping the valve disc open and the other end closed. Once the test pressure has been raised to the specified level, the valve body and valve cover are examined for any signs of leakage. If there is no leakage, the valve is considered to have passed the test.

Following this, the pressure is reduced to the test pressure for airtightness. The valve disc is closed, and the other end is opened for inspection. If there is no leakage, the valve is deemed to be qualified.

6. Pressure test method of check valve

Check valve test status: the valve disc axis of the lift check valve is in a vertical position perpendicular to the horizontal; the channel axis and valve disc axis of the swing check valve are roughly parallel to the horizontal line. During the strength test, the test medium is introduced from the inlet end to the specified value, and the other end is closed. If there is no leakage in the valve body and valve cover, it is considered qualified. During the tightness test, the test medium is introduced from the outlet end, and the sealing surface is inspected at the inlet end. If there is no leakage at the packing and gasket, it is qualified.

7. Pressure test method of a safety valve.

The safety valve strength test is quite akin to the testing procedures for other valves. Water is typically employed as the testing medium. When conducting a test on the lower section of the valve body, the pressure is applied from the inlet end and the sealing surface, effectively sealing it off. Conversely, when assessing the upper part of the valve body and the bonnet, the pressure is exerted from the outlet end and the other extremities, ensuring a comprehensive examination. To secure qualification, the valve body and cover must withstand this pressure for the specified duration without exhibiting any signs of leakage.

For sealing and constant pressure tests, different media are utilized depending on the type of valve in question. Steam safety valves utilize liquid steam as their testing medium, while ammonia or other gas valves employ air. Water and other non-corrosive liquid valves are tested with water. In critical positions, nitrogen is also utilized as the testing medium for safety valves. In these tests, the sealing pressure must meet or exceed the nominal pressure value, and it should be performed at least twice. It is considered eligible if no leakage is detected within the specified duration.

Two methods are commonly employed for leak detection. The first method involves sealing the safety valve joints and applying a thin layer of butter to the outlet flange. If the thin paper placed on the flange begins to bulge, it indicates a leak, while the absence of bulging suggests a sound seal. The second method entails attaching a plate or other sealing device to the lower part of the outlet flange and sealing the valve disc with water. Qualification is achieved if no bubbles are observed in the water. When conducting constant pressure and return pressure tests on safety valves, these tests must be repeated at least three times to qualify, provided they meet the specified requirements.