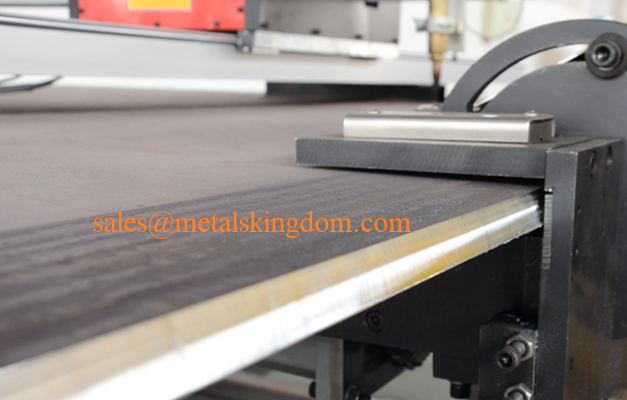

YM-100 Milling Type Plate Beveling Machine

1.Suitable for processing work piece materials with high rigidity, hardness, and heat resistance;

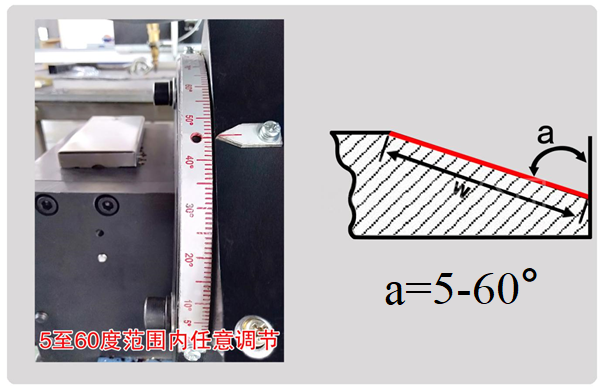

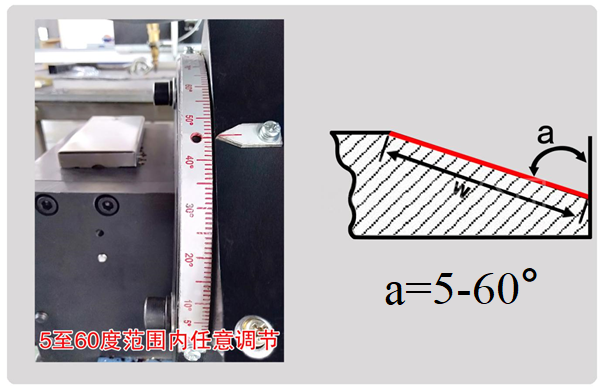

2.The angle range of the bevel can be adjusted freely within the range of 5° to 60°;

3.Rear mounted Reducer is beneficial for processing narrow plates and is more stable and safe;

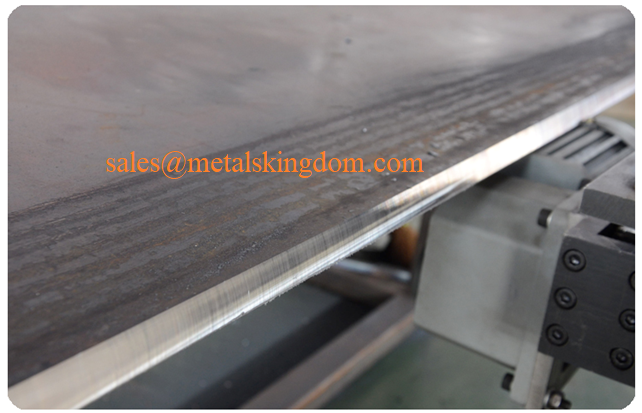

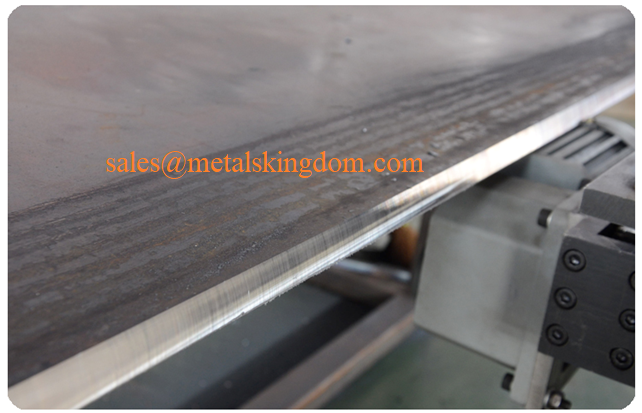

4.The surface smoothness of the processed bevel reaches Ra3.2-6.3, fully meeting the welding requirements of pressure vessels;

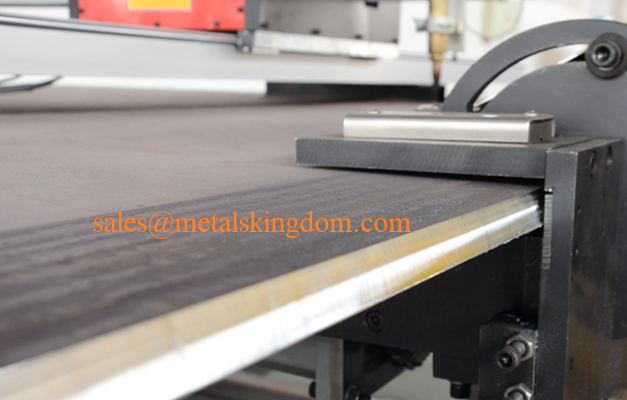

5.Small in size and light in weight, it is a portable automatic walking milling machine and also a moving and portable beveling machine;

6.Cold cutting bevel processing does not change the hardness of the material, and there is no oxide layer on the bevel surface;

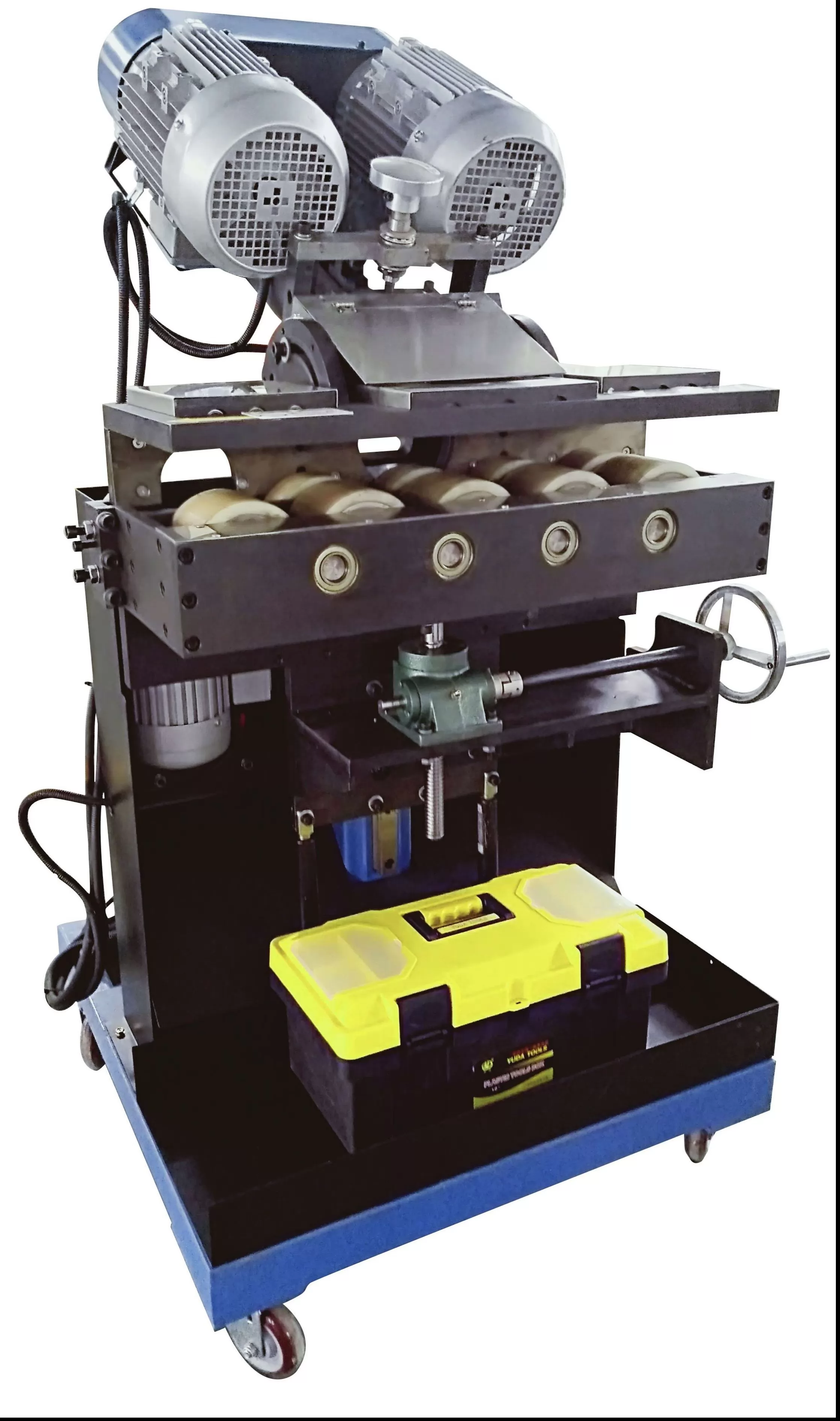

1.Product Introduction

This series of beveling machines is used for pre welding metal plate beveling. It mainly utilizes the milling principle to mill and cut the edges of the steel plate at the desired angle to obtain the required beveling for welding. It solves the disadvantages of high manual intensity, non-standard angles, rough slopes, and high working noise in flame cutting, polishing machine grinding processes, significantly reducing oxygen and acetylene gas energy consumption and labor costs. More effectively avoiding the disadvantages of deformation and hardness degeneration of the board after flame cutting; This machine can automatically walk according to the edge of the material, with convenient angle adjustment, easy operation, high efficiency, environmental protection, precise angle, smooth surface, and particularly outstanding characteristics for stainless steel processing.

Mainly used for ordinary structural steel, cast iron, hard plastics, stainless steel, non-ferrous metals and other materials in shipbuilding, metallurgy, pressure vessels, steel structures, petrochemicals, power, heavy industry, mechanical processing plants, mining and aerospace welding fields.

Specializing in stainless steel (pressure vessel) bevels.

2. Product Features

2.1 Suitable for processing work piece materials with high rigidity, hardness, and heat resistance;

2.2 The angle range of the bevel can be adjusted freely within the range of 5° to 60°;

2.3 Rear mounted Reducer is beneficial for processing narrow plates and is more stable and safe;

2.4 The surface smoothness of the processed bevel reaches Ra3.2-6.3, fully meeting the welding requirements of pressure vessels;

2.5 Small in size and light in weight, it is a portable automatic walking milling machine and also a moving and portable beveling machine;

2.6 Cold cutting bevel processing does not change the hardness of the material, and there is no oxide layer on the bevel surface;

3. Selection Parameters

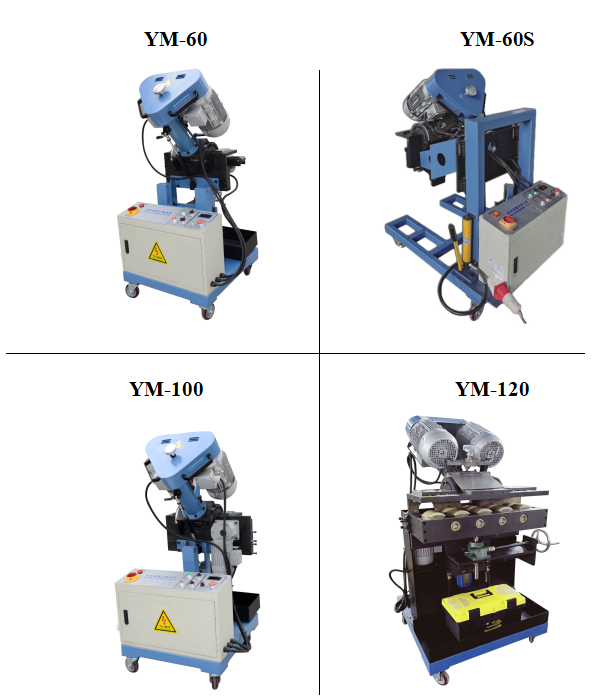

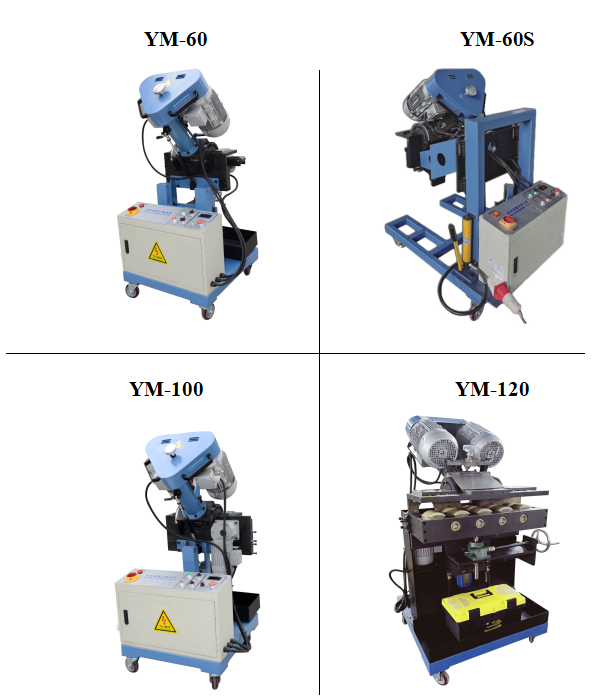

Parameters / Model | YM-60 | YM-60S | YM-100 | YM-120 |

Power supply | AC380V 50HZ | AC380V 50HZ | AC380V 50HZ | AC380V 50HZ |

Total power | 4.8kw | 4.8kw | 6.4kw | 6.4kw |

Main motor power | 2.2kw×2 | 2.2kw×2 | 3.0kw×2 | 3.0kw×2 |

Power of walking motor | 400w | 400w | 400w | 400w |

Feed Speed | 0-1.5m/min | 0-1.5m/min | 0-1.5m/min | 0-1.5m/min |

Cutter head speed | 1100r/min | 1100r/min | 1100r/min | 1100r/min |

Clamping thickness | 6-50mm | 6-50mm | 6-60mm | 8-100mm |

Clamping width | >80mm | >80mm | >80mm | >100mm |

Once bevel width | 0-20mm | 0-20mm | 0-20mm | 0-30mm |

Bevel width | 0-40mm | 0-40mm | 0-50mm | 0-50mm |

Number of blades | 6 pieces | 6 pieces | 6 pieces | 6 pieces |

Bevel type | V, Y | V, Y | V, Y | V, Y, U, J |

Bevel angle | 0°~60° | 0°~60° | 0°~60° | 0°~90° |

Processing material | Stainless steel, carbon steel, alloys, etc | Stainless steel, carbon steel, alloys, etc | Stainless steel, carbon steel | Stainless steel, carbon steel |

4. Series Products