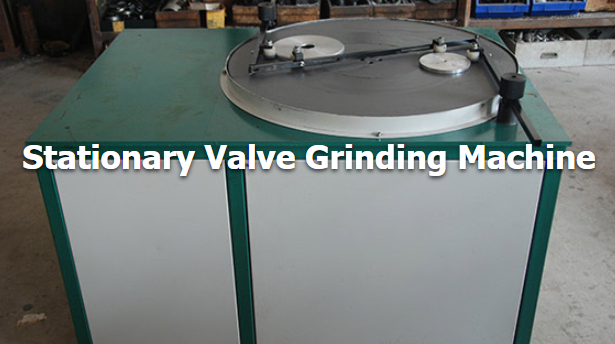

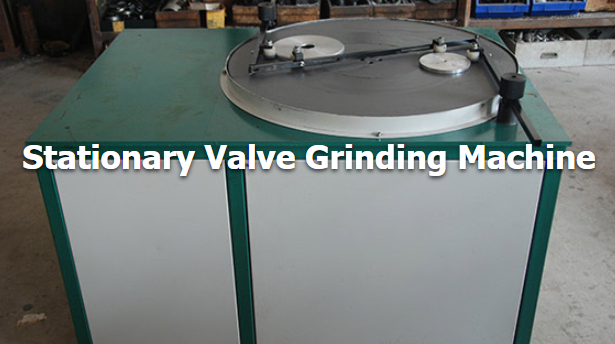

After the valve is used for a long time, the sealing surface of the valve disc and the valve seat will wear and the tightness will be reduced. Repairing the sealing surface is a large and important task. The main method of repair is grinding by Valve Grinding Machine. For the severely worn sealing surface, the first surfacing welding is followed by grinding and then grinding.

Grinding of the valve by the Valve Grinding Tool includes cleaning and inspection processes, grinding processes, and inspection processes.

Due to the different degree of damage, the valve flap and the seat sealing surface cannot be directly researched. Instead, the valve valve (ie, the grinding head) and the false valve seat (ie the grinding seat) are respectively used for the valve. Seat and disc are ground. The grinding head and grinding head are made of ordinary carbon steel or cast iron, and the size and angle should be equal to the valve disc and seat placed on the valve. If the grinding is performed manually, various grinding rods must be provided. Grinding rods and laps should be properly assembled and not skewed. In order to reduce the labor intensity and speed up the grinding, it is often ground by an electric grinder or a vibrating mill.