In terms of the specific types of grinders, the following will be referred to as CNC grinders, and CNC grinder manufacturers, for us, this grinder is also a website product and keywords. Understand so that you can learn successfully, and know how to properly use this kind of grinding machine, so as to obtain good results.

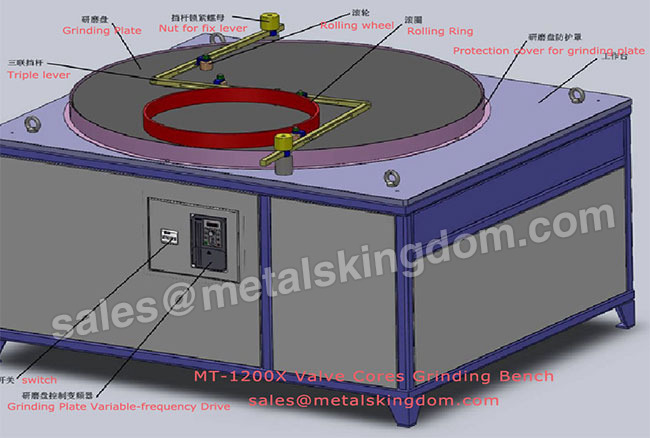

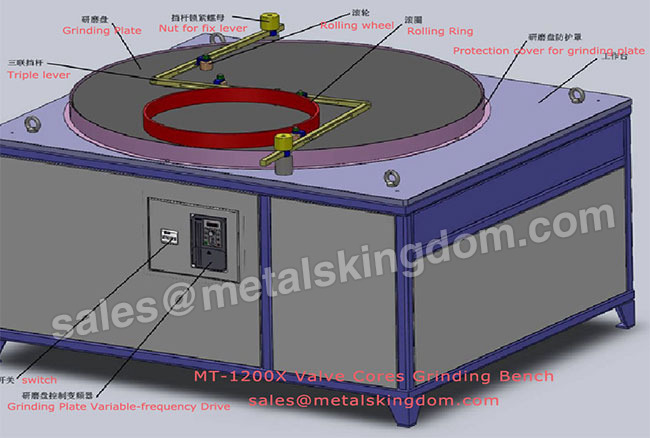

Valve Grinding Machine

1. Buying instructions for valve grinder machine

CNC grinder is a kind of grinder. It is necessary to know about the purchase. It is to consider all relevant factors, including detailed product parameters, performance indicators, origin, price, quality, manufacturer and after-sales service. These seven necessary considerations are indispensable. Moreover, we must comprehensively consider these factors in order to have accurate judgment and correct selection of results, and then to choose the right product.

2.The difference between ordinary grinder and CNC grinder

Ordinary grinders are driven by hydraulic cylinders, which use two axes to drive cylindrical grinding, and use two oil cylinders to control the feed of the wheel frame and the table, and manually control the grinding machine through the change of the dial. It is also controlled manually using measuring instruments.

The valve grinding machine of the CNC grinding machine manufacturer adopts the CNC system to realize the control, and the servo drive is used instead of the oil cylinder drive of the ordinary grinding machine. In addition, the servo system is used to realize the linkage control and cooperate with the on-line measuring instrument, and the linear grating to achieve the overall closed-loop control.

So, to sum up, there is a big difference between these two types of grinders, they cannot be equalized. Therefore, you must not make mistakes in its selection and use, so as not to cause problems or cause unnecessary trouble.

Comparison of CNC peripheral grinder and CNC tool grinder

CNC peripheral grinders and CNC tool grinders, these two are the specific types of CNC grinders, but when they are compared, there are some differences, as follows:

Difference 1: The degrees of freedom of the working parts of the equipment are different, and the degrees of freedom of CNC tool grinding machines are more.

Difference 2: The machining range is different. CNC peripheral grinding machines are used to grind workpieces with a certain angle, such as grinding the edge angle of complex contours, while CNC tool grinding machines can also change the angle for grinding.

Difference 3: In the scope of application, the scope of application of CNC tool grinding machines is wider than that of CNC peripheral grinding machines.

We are grinder equipment supplier. If you have any requirements for our products, please feel free to contact us.