Our company major business is grinder machinery, globe valve core grinder machinery, stationary valves grinder machinery and valve grinding machinery are our main products. Because our products are of good quality and excellent price, they have won unanimous praise from people inside and outside the industry.

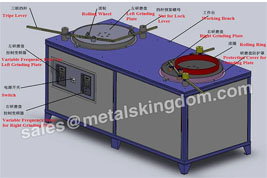

The characteristic of globe valve core grinder machinery is desktop structure and more stable and durable. The operation is simple and the efficiency is higher. Applicable Valves: Valve Core Grinding Range of Plane Stop Valve and Gate Valve: DN25-DN300 Power Supply Parameters: AC 380V/50Hz Motor Power: 1.5KW. Speed regulation mode: variable frequency smooth speed regulation grinding disc diameter: Global valve core grinder machine matters needing attention before working connect 380V power supply and turn on the total power supply of the equipment. Before starting the equipment, check whether there is any foreign matter around the grinding disc and handle it. Operating instructions: inverter operating instructions: equipment start key: RUN equipment STOP key: STOP forward/reverse conversion key: JOG Note: when forward/reverse conversion, the position of the triple stop lever should be adjusted accordingly Speed adjustment: knob rotation adjustment or up/down key adjustment on the panel Other keys are not recommended to be adjusted so as not to confuse the program. Grinding operation of valve core: Before grinding the valve core, adjust and fix the triple gear lever according to the size of the valve core, install the roller assembly on the triple gear lever, adjust the position and press firmly. Coat the grinding disc with grinding paste of corresponding granularity. Grinding repair of circular valve core: Place the valve core in the middle of the included angle between the three stop rods and contact with the roller to start the equipment for grinding. Or that roll ring of the valve core is place between the included angles of the triple stop rods and is in contact with the roll wheel, one or more valve cores are placed in the rolling ring, and equipment is started for grinding. Grinding of valve core of gate valve: Place the valve core rolling ring between the included angles of the triple gear rods and contact with the rollers, place one or more valve cores into the rolling ring, and start grinding. Hand-held grinding: place the small valve core with less damage on the grinding disc and start the equipment to grind with hands. Valve grinder is widely used in petroleum, chemical, metallurgy, electric power and other enterprises.

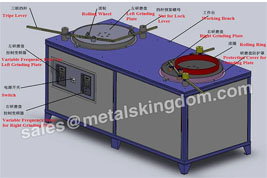

Our company’s stationary valves grinder machinery fixed valve grinding machine is suitable for valve discs of gate valves and stop valves, and is widely used in industries such as coal burning, electricity, petrochemicals, steel, gold paper, etc. Features: smooth, more stable and more durable ; easy operation and high efficiency ; grinding range: DN300-800mm; grinding valve type: disc, valve core of plane stop valve, gate valve, overflow valve