M series valve grinding machine is mainly used to repair the matching surface

of valves, flange sealing surfaces and other precision seals. It can close the

mating surface by grinding the valve core, valve seat and flange sealing surface

to achieve the valve and flange. The purpose of the seal. M series valve

grinding machine is suitable for the repair of sealing surfaces of gas

transmission, water delivery and oil delivery valves for power, petroleum,

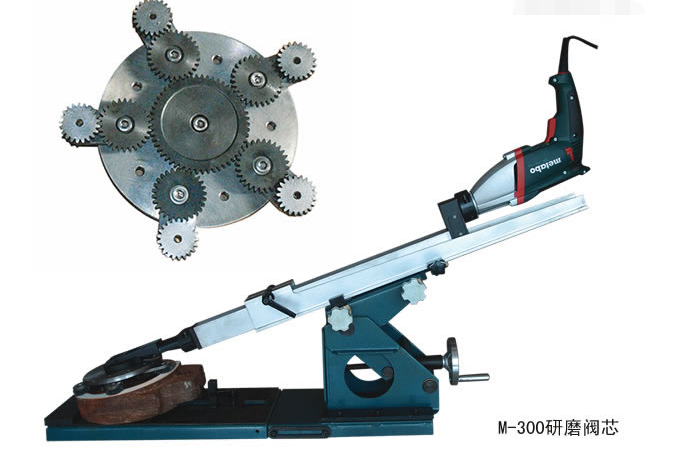

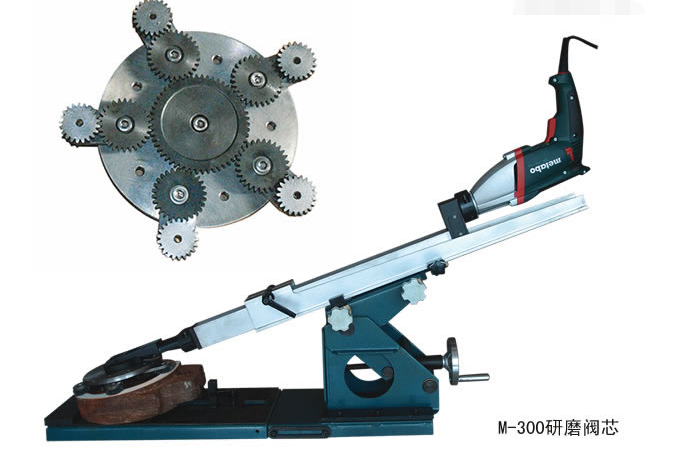

chemical, metallurgy, papermaking and other pipe valves. Valve Grinding Machines are mainly divided into portable and desktop types. Portable valve grinders are

suitable for in-line repair of inconveniently disassembled valves and repair of

site valves. Bench-top valve grinders are suitable for site valve repair.

The main features of the portable valve grinder:

★The product is a combined structure, easy to disassemble and easy to

install, and easy to operate.

★The fixed grinding disc is made of high-strength aluminum alloy. These

materials are high in strength, light in weight and resistant to

deformation.

★Standard configuration of German Metabo motors, all of which are

internationally renowned brands.

★ Grinding consumables are emery cloth (paper), which is low in cost and easy

to replace.

★The grinding speed is fast and the quality is good. The grinding efficiency

is 10-30 times that of manual grinding.

★The product is packed in aluminum and plastic box, which is small in size,

light in weight and easy to carry.

Scope of Portable Valve Grinding Machine

●Applicable to plane stop valve (spool, seat), cone stop valve (valve),

safety valve, etc.

●Equipped with special grinding disc to grind high pressure nozzle, equipped

with self-centering grinding disc to grind high and low pressure bypass

valve.