What does the valve testing equipment have?

For the use of the valve, its detection is indispensable, so what is the valve testing equipment? Below Grinder Equipment Supplier tells everybody to say.

Single-valued gauge: a gauge that reflects only one single value. It can be used to calibrate and adjust other measuring instruments or to compare directly with the measured quantity, such as measuring block, Angle measuring block, etc.

Multi-valued measuring tool: a measuring tool that can reflect a group of similar measuring values. It is also able to calibrate and adjust other measuring instruments or compare them directly with the measured standard, such as line ruler.

Special gauge: a gauge used to check a particular parameter. Common gauges are: limits of smoothness for testing smooth cylindrical holes or shafts, thread gauges for determining the eligibility of internal or external threads, test templates for determining the eligibility of surface profiles of complex shapes, functional gauges for testing assembly accuracy by simulating assembly passability, and so on.

General measuring tool: the measuring instrument with simple structure is called general measuring tool in our country. Such as vernier caliper, outside micrometer, dial indicator, etc.

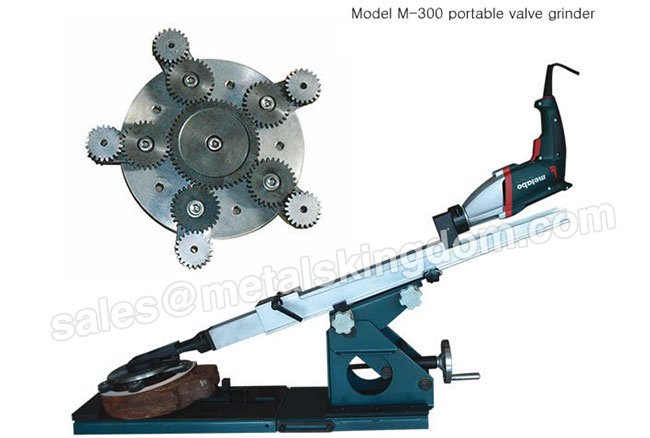

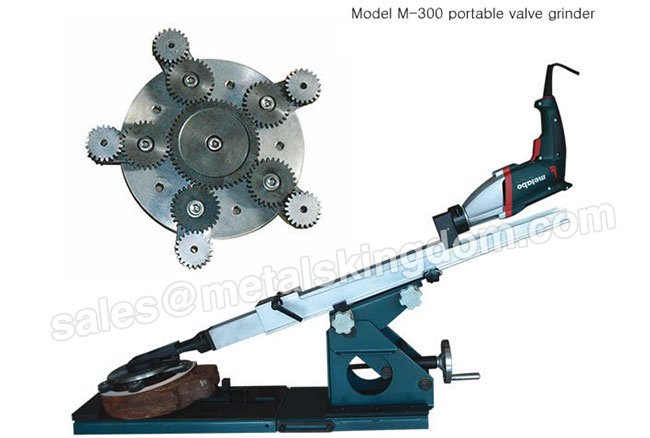

M-300 Portable Gate Valve Grinding Machine

Several rules to follow for valve pressure test equipment:

Now many valves need to be tested before they can be put into use, so the valve pressure testing equipment to follow a few rules? Follow valve testing machinery supplier to have a look together below.

1. For the valve in the form of welded connection, if the pressure test fails with blind plate, it can adopt conical seal or o-ring seal for pressure test.

2. Generally, the valve shall not be tested for strength, but the body and bonnet repaired or corroded shall be tested for strength. For safety valve, its constant pressure and back pressure and other tests should comply with its specifications and related regulations.

3. Valve installation should be tested for strength and tightness. Low pressure valve sampling inspection 20%, if unqualified should be 100% inspection; Medium and high pressure valves should be 100% inspected.

4. The pressure should be gradually increased during the test, and it is not allowed to increase the pressure sharply and suddenly.

5. During the test, the valve should be installed in the direction that is easy to check.

6. Try to remove valve air during hydraulic test.