MZ150 DN50-150mm (2-6Inch) Portable Gate Valve Grinding Machine

Technical indicators

Applicstion:Gate Valve Seat,Gate Valve Core.

Grinding diameter: D=Dia50-Dia180mm adjustable

Valve DN:DN50-150mm

The electrical power: 1100W (Electric motor)

The greatest adjustment depth: 420 mm

Input voltage: 220 V

Operating weight: 20 kg

The smallest broaching size: B = 38mm

1.Summarization

MZ Portable Valve Grinding Machine for grinding gate valve is a new generation of products that is adeveloped to adapt to on-site maintenance gate valve. It has the advantages as below: the reduction of labor intensity, improving labor efficiency, replacing imported products, educing the maintenance cost. It is widely used in petroleum, chemical industry, steel mills, power plants and so on.

1) small volume. Light weight, easy to carry.

2) installation is simple, the structure of product is combined type, easy disassembly, transvestite.

3) easy to operate.Valve seat, valve core can be grinded.

4) high grinding efficiency, good quality. Using advanced grinding materials, grinding efficiency is 10 to 30 times that of the manual grinding, can make the contact area of more than 95%. High precision grinding quality makes the contact area to the level of new valve.

5) it is suitable for on site repair in a complicated environment which saves the overall disassembling of valve.

2.Technical indicators

| Item | MZ-150 | MZ-250 |

| Grinding Range(mm) | Dia 50-180 | Dia95-270 |

| Voltage(V) | 220 | 220 |

| Power(W) | 1100 | 1100 |

| Frequency(HZ) | 50 | 50 |

| Max Grinding Depth(mm) | 420 | 600 |

| Valve sealing face min gap(mm) | 38 | 45 |

| Gross Weight(kg) | 20 | 31.5 |

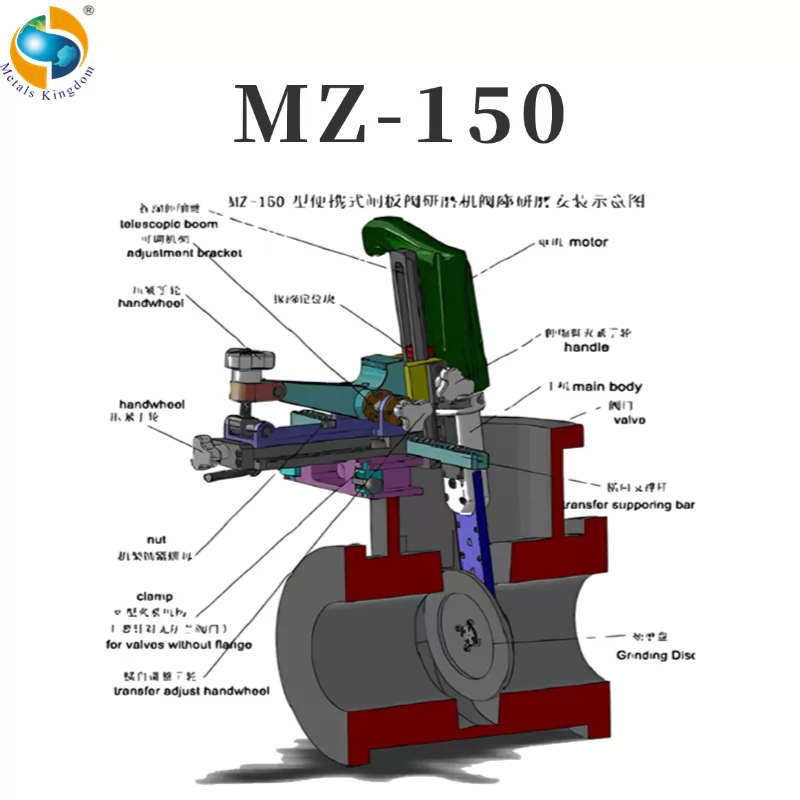

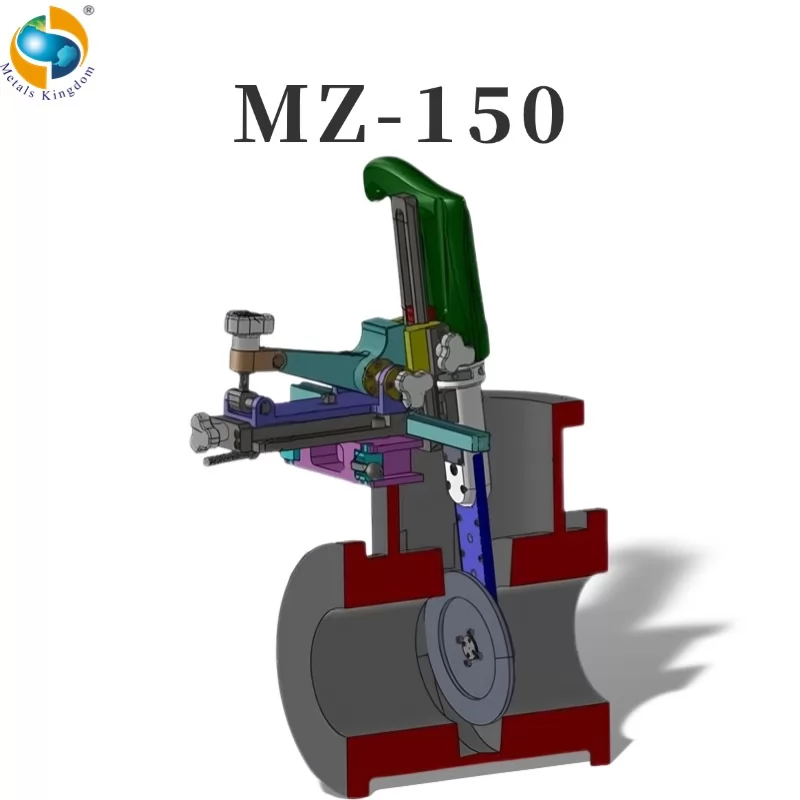

3.The installation diagram