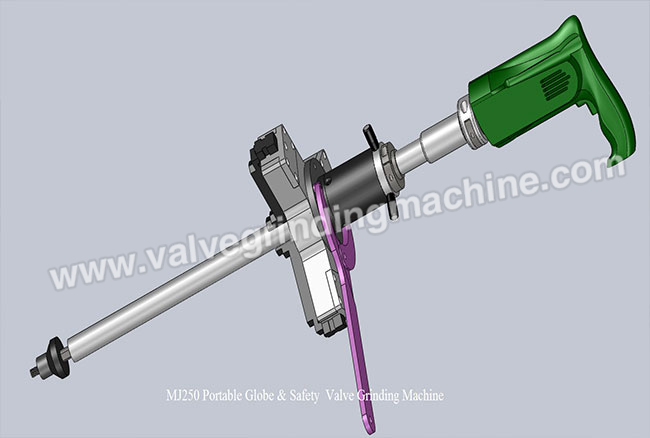

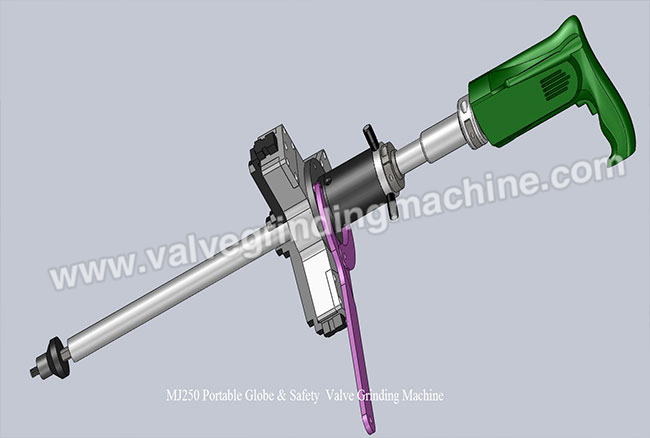

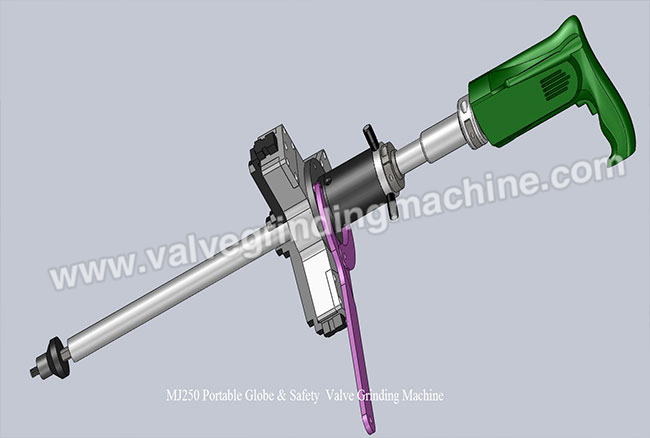

MJ-300 DN20-300mm (1-12) Portable Globe&Relief Valve Grinding Machine

1)grinding diameter: Dia20-Dia335mm DN20-300mm

2)used for valve seat of plane globe valve,valve seat of safety valve ,

3) spindle speed(rpm):0-900,0-2800

4)the maximum grinding depth: 450 mm

5)Power supply: 220 V/50Hz

6) motor power: 1100W

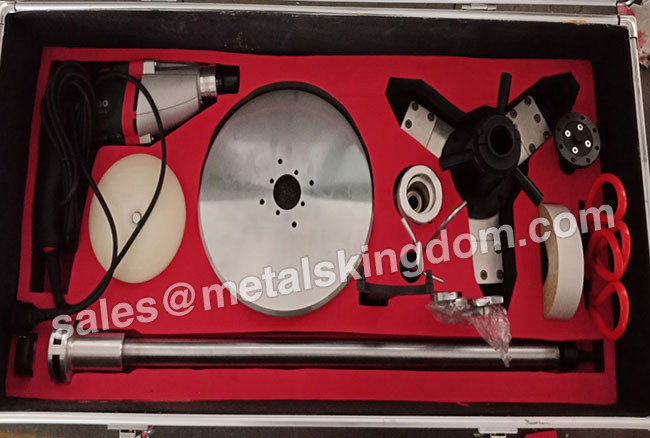

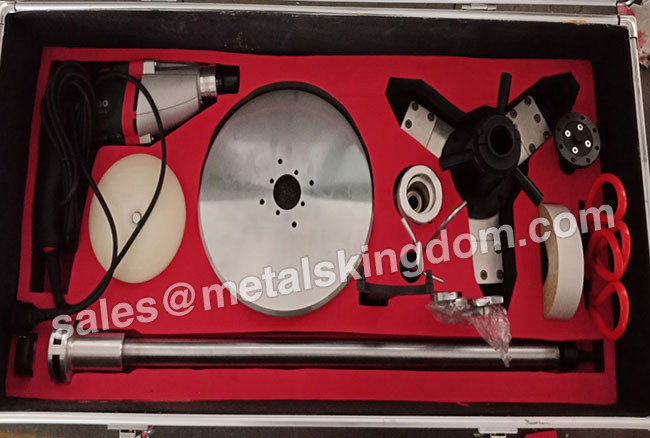

1. Product picture

2.MJ-300 Portable Globe Valve Grinding Machine Summarization

MJ-300A Portable Valve Grinding Machine is a new generation of products that is adeveloped to adapt to on-site maintenance gate valve. It has the advantages as below: the reduction of labor intensity, improving labor efficiency, replacing imported products, educing the maintenance cost. It is widely used in petroleum, chemical industry, steel mills, power plants and so on.

1)small volume. Light weight, easy to carry.

2)installation is simple, the structure of product is combined type, easy disassembly, transvestite.

3)easy to operate.

4)high grinding efficiency, good quality.

5) it is suitable for on site repair in a complicated environment which saves the overall disassembling of valve.

3.MJ-300 Portable Globe Valve Grinding Machine Technical indicators

1)grinding diameter: Dia20-Dia335mm DN20-300mm

2)used for valve seat of plane globe valve,valve seat of safety valve ,

3) spindle speed(rpm):0-900,0-2800

4)the maximum grinding depth: 450 mm

5)Power supply: 220 V/50Hz

6) motor power: 1100W

4.Operation:

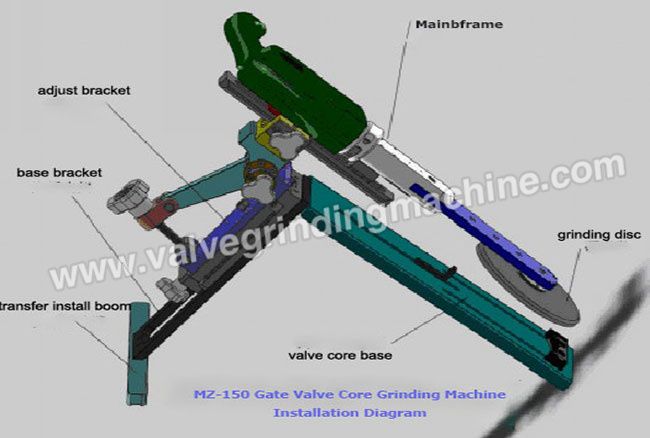

1. The valves DN80 minimum are fixed by three claw frame components

(1) Adjust the position of the block according to the different size of the valve. Then, the probe arm assembly is inserted into the hole of the three jaw frame .Select the appropriate grinding head with good pressure or sandpaper, then the grinding head is fixed by the nut firmly.

(2) Put the three jaw frame assembly together with the probe arm assembly into the valve,fix the frame components on the valves by the special wrench.Then press the hand wheel clockwise to the end,lift the arm components to the valve sealing surface 2-5mm.and then Six angle wrench is used to lock the locking block.

(3) The motor is installed on the motor seat and locked, and the power supply is switched on. To move the motor running, confirmed no abnormal, the pressing wheel counterclockwise rotation of the grinding head into contact with the sealing surface, to rotate counterclockwise pressing wheel make grinding head pressure to the appropriate pressure after grinding, until finish grinding.

(4) In the grinding process if for replace sandpaper, should first stop, then rotate clockwise pressing wheel make the grinding head contact the sealing surface. Use special wrench loosen the three claw frame, together with the transmission components together, the replacement of sandpaper. The replacement of the three jaw frame will be completed together with the transmission components up tight to the valve, the same steps grinding.

Note:

(A) Plane globe valve grinding assembly for grinding plane globe valve body.

(B) Cone valve assembly for grinding cone valve seat should be used together with head dial transposition.

(C) Before install plane grinding head with more than Dia175mm, the large plane grinding head connecting piece is mounted on the grinding head. and then mounted together plane valve grinding assembly.

2.

(1) the Installation operation for the plane grinding head with less than Dia50mm :

Fit the small universal head on the short drive shaft, and then together are installed on the motor seat. The motor is mounted to the motor seat locking,install the grinding head and then can grind

(2) the installation operation for Dia50-90mm plane grinding head:

the grinding head is fitted to the plane valve grinding assembly,motor is installed and then can grind.

(3) the installation operation for letss than Dia32mm Cone Grinding head:

The centering sleeve and the grinding head is mounted to the short drive shaft, and then put together to the motor base. The motor is installed to the motor base locked,can grinding.

(3) the Installation operation for Dia32-90mm Cone Grinding head

The centering sleeve and the grinding head is mounted to the long drive shaft, and then put together to the motor base.The motor is installed to the motor base fasten,and can grind

2. Grinding Technology:

1) Coarse grinding: grinding with sandpaper around 80#, removal the defect such as groove mark,pits and scratches and etc.

2) Accurate grinding: with sandpaper about 240#, to remove minor scratches.

3) Polishing: with more than 400# sandpaper, to achieve the purpose of polishing the sealing surface.

4) before sticking the sandpaper, grinding disk should be coated with a layer of bolt looseness agent and wipe up, thus it is easy to replace the sandpaper.