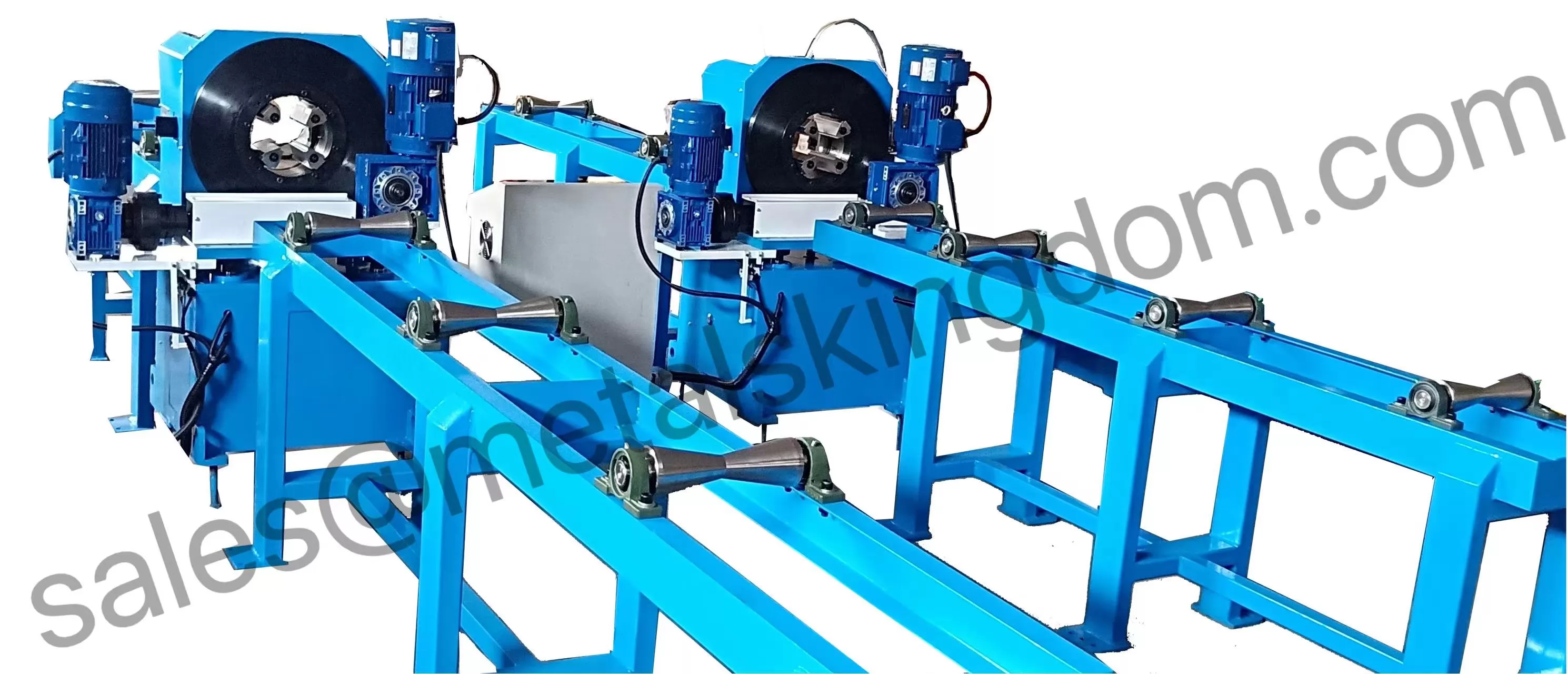

CDM-168 Stationary Pipeline Cutting Beveling Machine

Main Technical Parameters of CDM-168

Model: CDM-168

Cutting range: 30-168 mm

Center height of the body: 780-960 mm

Main motor power: 2.2KW

Lifting method and lifting motor power: Automatic 0.75KW

Clamping method and clamping motor power: Electric/hydraulic 4-claw centering 1.1KW electric/1.5kw hydraulic system

Cooling method and water pump motor power: Circulating water cooling/90w

Cutter head speed: 0-40r/min

Maximum cutting wall thickness: ≤30mm

Feed method/quantity: Automatic feed /0.07-0.1mm/min

Input power supply: AC380V/50HZ

Bevel form: V/I/U/ Dual V type

Frequency: 50HZ

Cutting the shortest length: 250mm

1.Equipment principle:

The pipe is clamped in place, the cutterhead rotates, and a mechanical ratchet is used for cutting; During processing, the pipe is clamped with self centering at multiple points around the circumference, and the cutterhead rotates along the outer diameter of the pipe. The cutting is inserted layer by layer until the processing is completed. After processing, the pipe is not deformed, and the surface of the straight or bevel is smooth, with good verticality of the end face, which can be directly used for welding.

2.Processing capability:

Single feed completion of cutting + synchronous completion of beveling processing.

3. Performance characteristics:

1) Used for standard bevel machining of pipeline end faces, and can also be used for cutting and bevel machining of the middle position of pipelines.

2) After cutting, it can be directly welded, with high surface smoothness and no deformation during processing.

3) Rotary cold cutting, rotating blades cut along the periphery of the pipeline, with good cutting effect and vertical end face.

4) Can be used to process any pipe, such as carbon steel, stainless steel, alloy steel, etc.

5) Adopting multi-point circumferential clamping effectively avoids pipeline clamping deformation.

6) The main body of the cutting and beveling machine can be lifted and lowered to meet the adjustment of the center elevation during the processing of pipes with different diameters. The operation is simple and convenient to use.

7) Compact in structure, lightweight, and easy to carry, it can be used for fixed use in the workshop or for on-site processing.

4. Equipment configuration

Basic configuration |

Machine head | Cutter head variable frequency speed control system |

Elevator base | Electric or hydraulic clamping system |

Circulating water cooling system | Pipe conveying roller conveyor (optional components, input end length is selected according to the length of the raw material pipe, and output end length is selected according to the length after cutting. There are two options for manual or electric drive) |

5.Technical Parameter

Model | CDM-168 |

Cutting range | 30-168 mm |

Center height of the body | 780-960 mm |

Main motor power | 2.2KW |

Lifting method and lifting motor power | Automatic |

0.75KW |

Clamping method and clamping motor power | Electric/hydraulic 4-claw centering |

1.1KW electric/1.5kw hydraulic system |

Cooling method and water pump motor power | Circulating water cooling |

90w |

Cutter head speed | 0-40r/min |

Maximum cutting wall thickness | ≤30mm |

Feed method/quantity | Automatic feed /0.07-0.1mm/min |

Input power supply | AC380V/50HZ |

Bevel form | V/I/U/ Dual V type |

Frequency | 50HZ |

Cutting the shortest length | 250mm |

Processing capability | Multiple feed completion cutting+single bevel/or double bevel |

Quantity of cutting tools participating in processing simultaneously | 1 or 2 |

Applicable materials | Carbon steel, alloy steel, stainless steel, low-temperature steel, heat-resistant steel, etc |

6.Selection parameters

Model Parameter | CDM-168 | CDM-325 | CDM-406 | CDM-508 | CDM-610 | CDM-711 | CDM-813 | CDM-914 |

Applicable pipe diameter(mm) | Φ30-168 | Φ80-325 | Φ219-406 | Φ325-508 | Φ406-610 | Φ508-711 | Φ610-813 | Φ711-914 |

Cutter head speed(rpm) Continuously variable speed | 0-40 | 0-30 | 0-22 | 0-20 | 0-17 | 0-15 | 0-10 | 0-8 |

Main motor power(KW) | 2.2 | 3.0 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 |

Clamping method | 4-claw centering | 6-claw centering | 8-claw centering |

Clamping drive | Electric or hydraulic | Hydraulic |

Main lifting method | Electric |

Maximum wall thickness(mm) | 5-25 |

Cold cutting method | Circulating water cooling |

Feed rate | 0.07mm/r |

Bevel type | V/I/U/ Dual V type (standard with 30 ° V type) |

Feed method | Rotary radial automatic feed |

Applicable materials | Carbon steel, alloy steel, stainless steel, low-temperature steel, heat-resistant steel, etc |

Input power supply | AC 380V 50Hz |